How To Put A Track Back On A Mini Excavator

Mini excavators are fantastic tools for a wide variety of jobs. They can maneuver into tight spots and perform plenty of tasks — unless their tracks fall off. When a rails comes off of a mini excavator, it can be a frustrating feel, especially if it happens repeatedly. Loose tracks tin lead to detracking and premature wear and tear, along with expensive replacements. Thankfully, y'all don't need an expert to put the rails back on, and keeping the track from loosening in the beginning place simply requires a piffling maintenance. Learn more than virtually what to do when a runway comes off a mini excavator and how to put tracks back on. Mini excavators tin lose their tracks more than or less ofttimes depending on usage. A heavily used machine will lose tension more than apace than one that sees calorie-free utilize. Certain environments can too contribute to tension loss and make an excavator more likely to lose its tracks. Harsh terrain can also affect the tracks' tension and cause it to pop off more frequently. Following appropriate maintenance and keeping a close eye on your components can assist you detect any losses in tension and help you foreclose losing tracks. So how exercise you tell if your tracks are getting loose? Fortunately, mini excavators provide you with quite a few signs to alert yous of this condition. Below are some of the telltale signs that your mini excavator tracks are getting loose. The sprockets take intendance of the rotation of the track. They typically interlock with and move information technology around, but if they start to skip over lugs, you may have an outcome. If they aren't interlocking appropriately, the track tin come off. The skipping is a sign that your track may be loose or your sprocket is worn. Keep an eye on the status of the sprockets. As you may expect from something made of rubber, tracks stretch with use. Check the tension regularly, depending on how often you employ the excavator. If you use it heavily, check it every few days. To bank check the tension, lift the tracks off the ground by moving the nail to one side and pushing it onto the ground. And so, examine the distance between the eye roller and the track. Cheque manufacturer specifications for a specific length to look for. An inch betwixt roller and rails tends to be average. If the distance is too wide, the wheels need tightening. Paying attending to rail tension tin help you extend the excavator's life and go on components in proficient status. Missing lugs can spell trouble for your runway tension. The lugs may come out from sprockets slipping against them or if they are damaged. Look at the status of the parts regularly to make sure they aren't affecting the tension of your tracks. Supersede any missing lugs right abroad. Usage will touch the rubber on the outside of the tracks. Certain environments, like rocky terrain, tin more than quickly cause cracks to appear, and so can heat or sun exposure. Once cracks prove up, y'all should supplant your tracks. High-quality rubber can amend resist cracking, and storing your mini excavator out of direct sunlight can help. Deterioration can similarly cause premature vesture on your tracks. If they are exposed to excessive heat, damage or sunlight, yous may find stress marks or even rotting rubber. If your tracks begin to deteriorate like this, it's time for a replacement. Fortunately, many of these problems are preventable with regular maintenance of your meaty excavator. We'll get into track maintenance tasks afterwards, but first, let's take a wait at what happens if your tracks do manage to come off of your mini excavator. Putting the tracks back on a mini excavator doesn't require any advanced knowledge, only a little elbow grease — and some real grease, of course. Thankfully, information technology's a relatively quick process, though yous'll probably need a friend to assist you out. Yous will demand: Here's how to ready your tracks: That's all it takes to get your track reattached to the mini excavator then yous tin can continue moving. If you think your machine might be configured in a unique style, it may help to check the possessor's transmission for more information on where sure components are, such every bit the grease plumbing fixtures. The reasons that tracks can come off of a mini excavator are numerous, but non too difficult to address. With proper maintenance and a watchful eye, you tin can keep your tracks in place. Below are some of the reasons your tracks may come off and what you can do to foreclose it from happening again. Tension is a common crusade of loose tracks. Tension can change throughout the life of your tracks, and different applications require dissimilar tensions. The manufacturer should provide you with a recommended tension level, often in the form of the distance between the roller and the tracks. While knowing the recommended tension tin help you maintain a general tension level and ensure it doesn't go likewise loose, specific driving conditions may warrant special attention. Soft footing might require tracks with more slack, while hard or rocky ground may need slightly tighter tracks. Loose and tight tracks are both problematic, so you'll demand to go them just right to avert difficulties. When tracks are too loose, y'all run a risk the rails coming off during operation, particularly while taking turns or traversing an uneven surface. Detracking can be dangerous to anyone in the vicinity, plus the tracks are difficult to reattach. Tracks that are too tight, on the other mitt, increase wear and tear on your excavator. Components volition see unnecessary strain and may not terminal as long as they should. Another significant component of getting the right tension is knowing the departure between the needs of steel and condom. Rubber tracks typically need to be tighter, while steel tracks can be looser. Steel doesn't flex and needs a way to relieve the buildup of tension from whatever fabric that gets stuck in the tracks. Condom tracks are more flexible, so they tend to adjust to these objects on their own and don't lose equally much tension when they appear. Tightness should be adapted if switching betwixt steel and safe tracks. Always check the manufacturer'south specifications to know what this should look like. Mini excavators sometimes get put through the wringer thanks to use in harsh environments. They might be establish in terrain that is rocky, dingy, sandy, soft or filled with rubble. Keeping them clean and in good condition tin can exist hard but it is a vital step toward extending the life of your equipment. Rollers need to move smoothly and flanges should not be wearisome and rounded. Worn sprockets are a mutual problem area and can affect track stability. Of form, inspecting these elements requires them to be cleaned. Removing a layer of mud lets you come across any signs of article of clothing and tear. Wash your automobile subsequently each use and thoroughly audit information technology, looking for any worn parts. Any dirt and debris that stick in the undercarriage can cause your tracks to wear from the within. Materials similar droppings, mud, gravel and rubble that get stuck in the tracks tin can go compacted over time. Compacted cloth increases the tension on the tracks. To clear information technology, go far the addiction of raising the tracks and running them quickly to clear out the debris. You tin also lower tension by releasing grease. When you put grease into the motorcar, what you're really doing is pushing an adjusting piston in a way that increases pressure on the tracks. The mechanism is what tightens the tracks. If the piston is rusted, aptitude or otherwise deteriorating, information technology can loosen over time and crusade tension to fall away, loosening your tracks to an unacceptable level. A faulty adjuster piston may be what causes the tracks to fall off. To encounter if this is the case, tighten your tracks in the morn and bank check the tension throughout the day. If it falls apace, the piston could very well be your problem. While we all similar to think nosotros're great drivers, crude performance can exacerbate many issues from loose tracks. Recall to follow safety guidelines and drive carefully. It'due south important to buy tracks that fit your equipment. Tracks that are ill-plumbing equipment or poorly made will see a host of issues, including reduced tension. Some signs that your track doesn't fit correctly include: To find the right size, compare the new tracks with your previous ones, check with the manufacturer or give u.s. a call. Our staff is full of professionals who deal with track sizing every twenty-four hour period and tin can assistance you lot find the right ones. Poor structure practices or depression-quality materials tin can also affect your tracks' performance. Too much flexibility is a common problem with poor-quality tracks. If the cables within the tires are weak or the textile is too thin, the tracks could easily lose their rigidity. Durable tracks are a necessity for the environmenthow s that many mini excavators are in. High-quality rubber can better stand to lord's day damage or high oestrus exposure, too. Depending on your work environment, this may exist an important factor in your workday and could pb to early wear if non addressed. Don't forget well-nigh matching your tracks to the industry you're in. Demolition and construction sites demand durable tracks, perchance steel, while landscapers might need gentler, shine tracks that won't damage the ground. Other industries have unique needs, and fitting your tracks to the task tin offering a variety of benefits. When information technology comes to ownership loftier-quality, well-fitted tracks, the professionals at McLaren Industries are ready to help. Nosotros know tracks and can help you find the right ones for your motorcar, industry and needs. Nosotros have tracks for mini excavators from major brands similar CAT®, John Deere, Kubota and more. In addition to tracks that are well-fabricated, our design designs provide exceptional performance in diverse atmospheric condition, like snow, mud and rocky footing. Our NextGen premium-quality track series, designed to optimize the life of undercarriage components, helped solidify McLaren as a leading rubber track manufacturer worldwide. We've fifty-fifty come upwardly with a HYBRID series of steel and safety tracks that are almost indestructible. All of these products are available for mini excavators and are backed by the expertise and back up of McLaren Industries, where we've been keeping mechanism moving for over 25 years. Request a quote or give u.s.a. a call today at (800) 836-0040 for help choosing the correct mini excavator tracks for your next chore. How Oftentimes exercise Mini Excavators Lose Tracks?

Signs Your Tracks May Be Coming Loose

1. Sprocket Bug

2. Lost Tension

iii. Missing Lugs

four. Bully

5. Deterioration

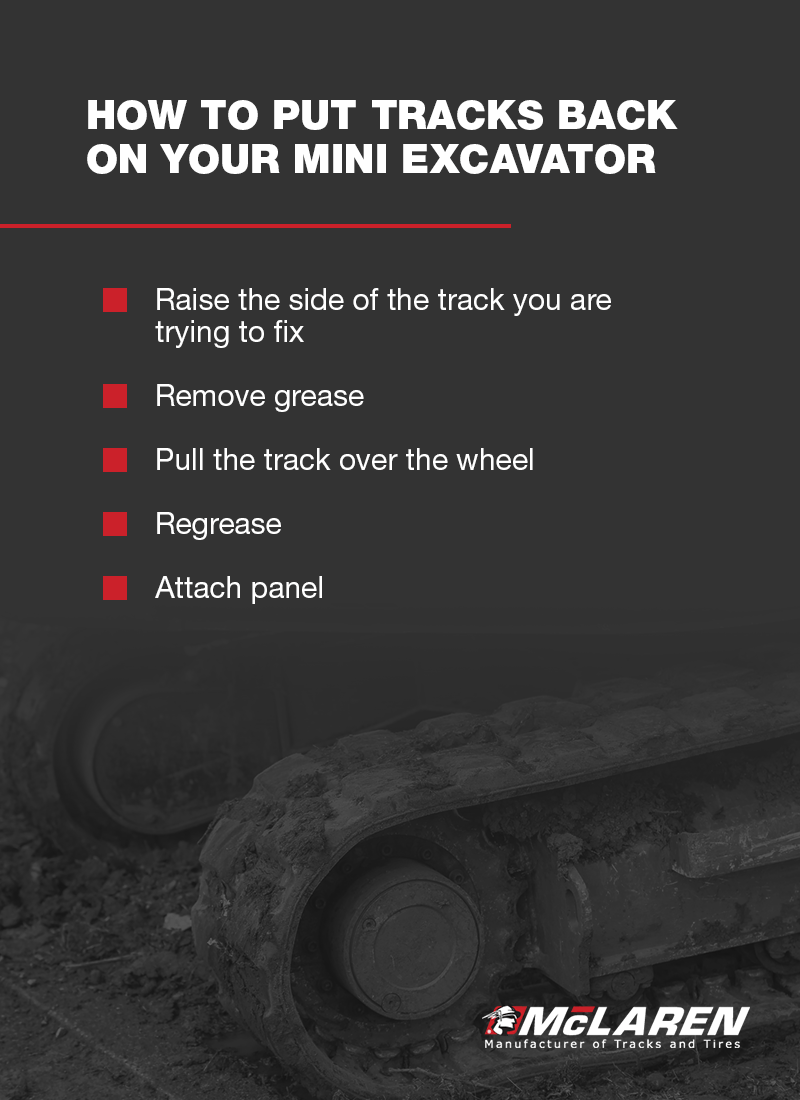

How to Put Tracks Back on Your Mini Excavator

How to Preclude Tracks From Coming Off a Mini Excavator

1. Check Your Tension

two. Keep Components and Undercarriage Clean

3. Make Sure the Adjuster Piston is Working

4. Follow Best Practices for Operation

5. Purchase the Right Tracks

Find the Correct Tracks with McLaren

Source: https://www.mclarenindustries.com/us/en/news-and-resources/articles/243/how-to-put-tracks-back-on-a-mini-excavator/

0 Response to "How To Put A Track Back On A Mini Excavator"

Post a Comment